Design &

Development

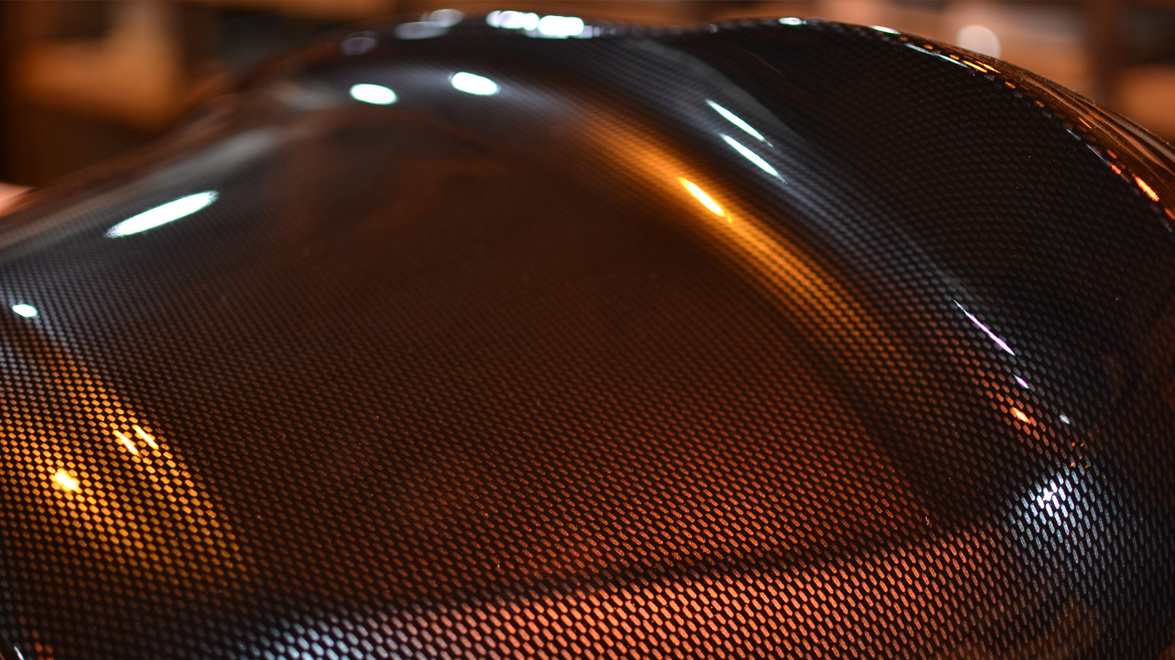

Product Design

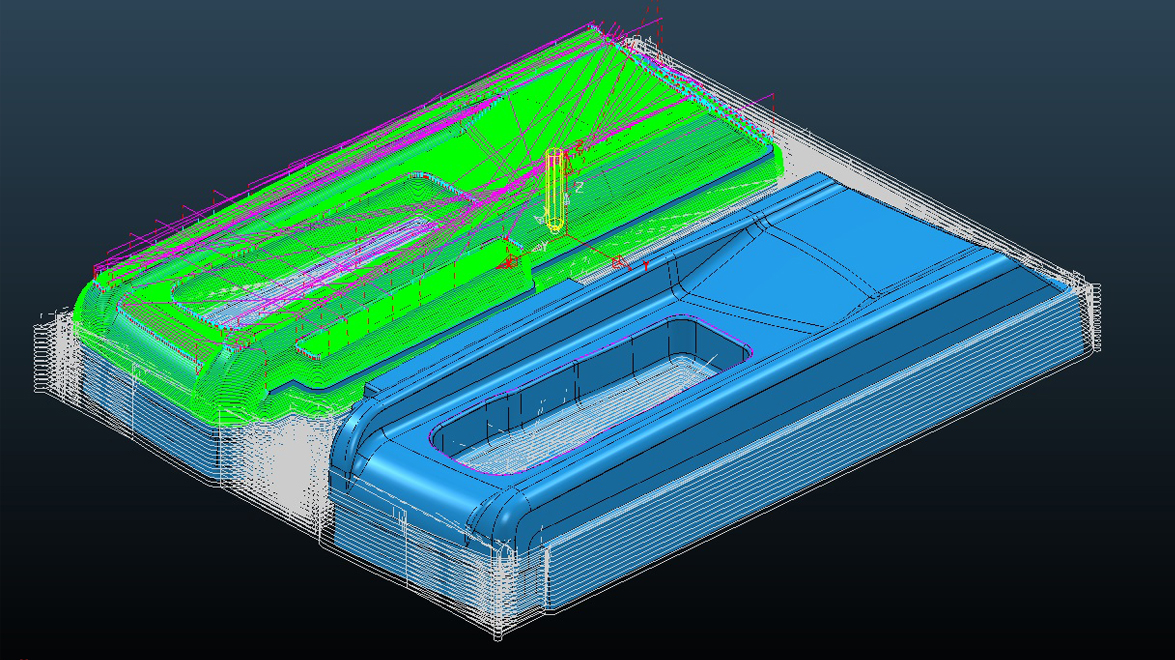

Our designers have the necessary background and experience to understand the importance of innovation, aesthetics, product functionality and cost. Our design team uses an advanced CAD/ CAM software package that supports all common industry standards and can work from a simple line drawing, right through to fully rendered artwork/ CAD data. This focus on specific design requirements dictates our ability to produce parts cost effectively and to full customer specification.

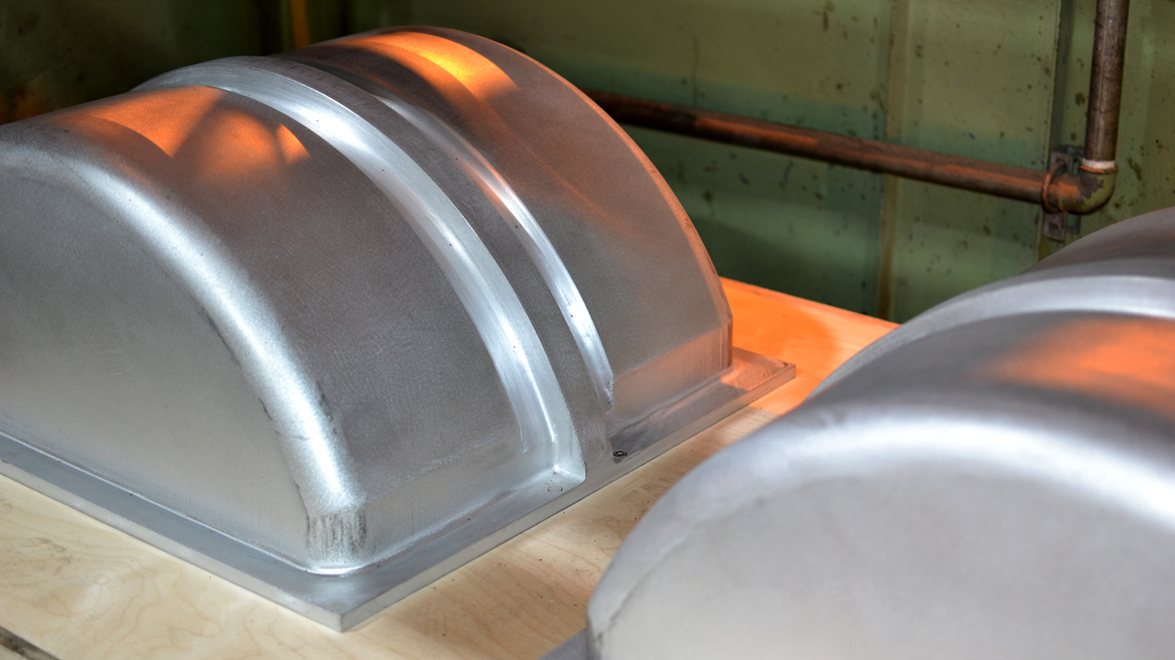

Rapid Prototyping

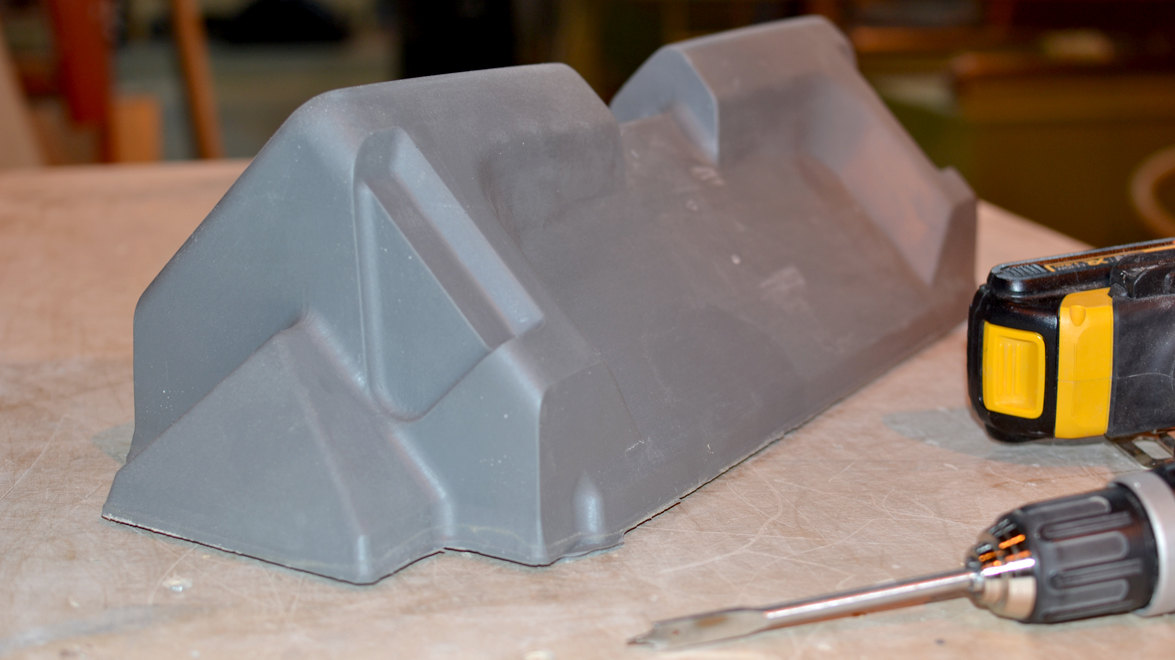

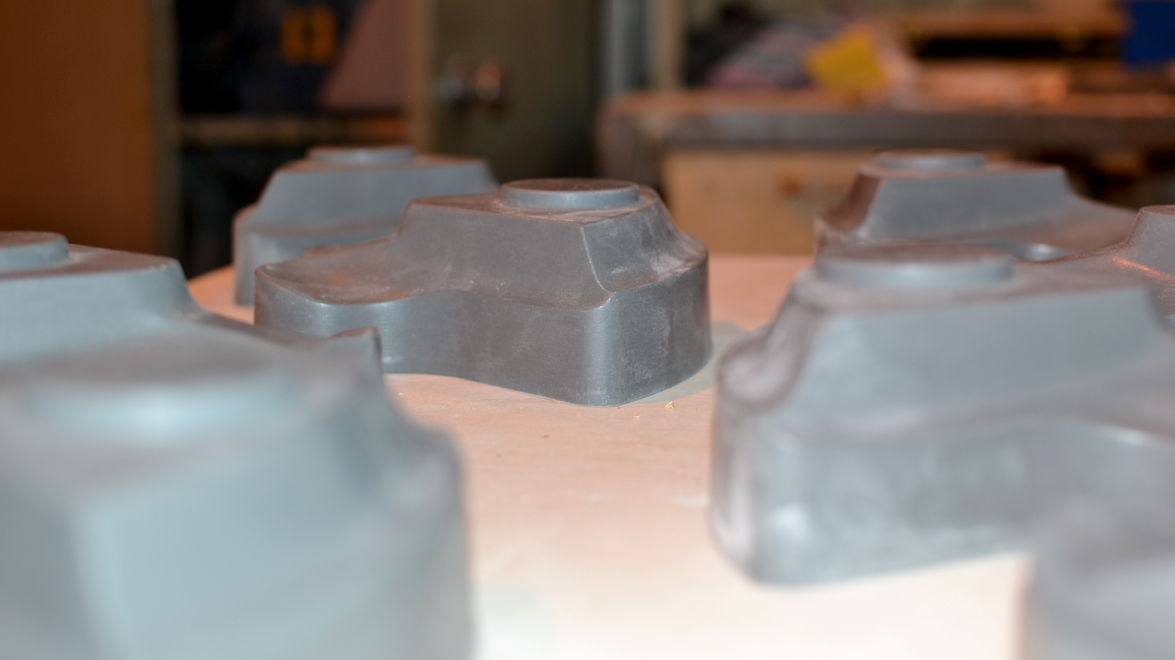

ESP understands the significance of the prototyping phase within the design process and generates production quality prototypes of the final product to ensure they are fully representative of our customers design, before committing to production tooling. Our team's use of Reverse Engineering, Custom Models and 3D CAD to produce rapid in-house prototype tooling has helped to reduce this first part of the production process and increase speed to market.

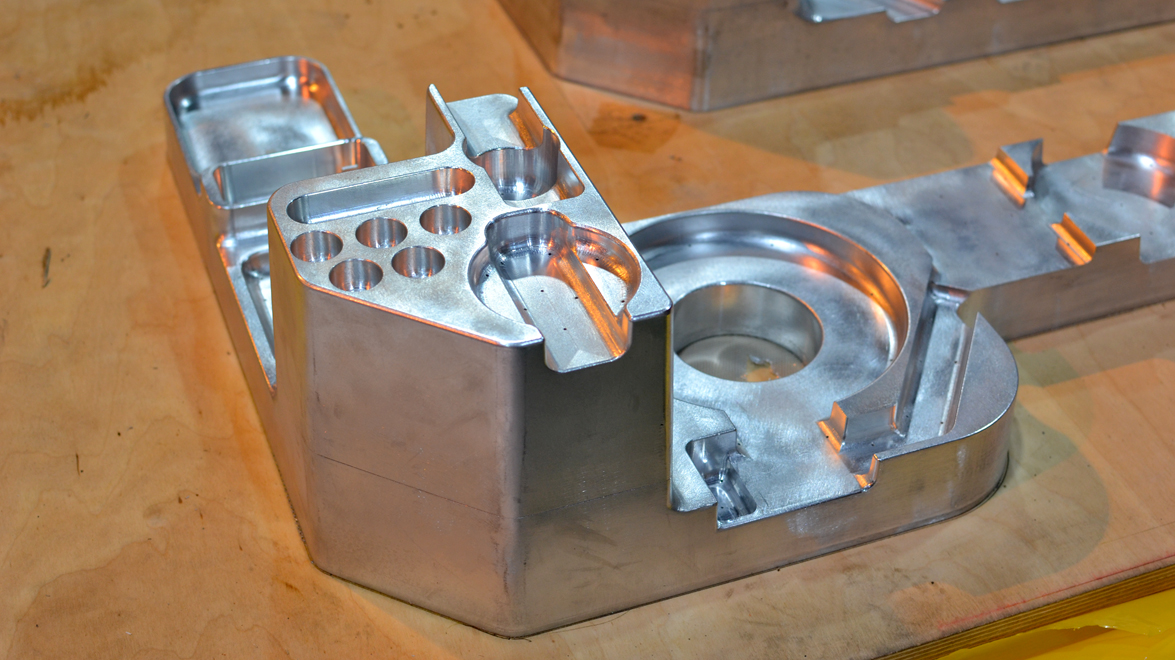

Tooling

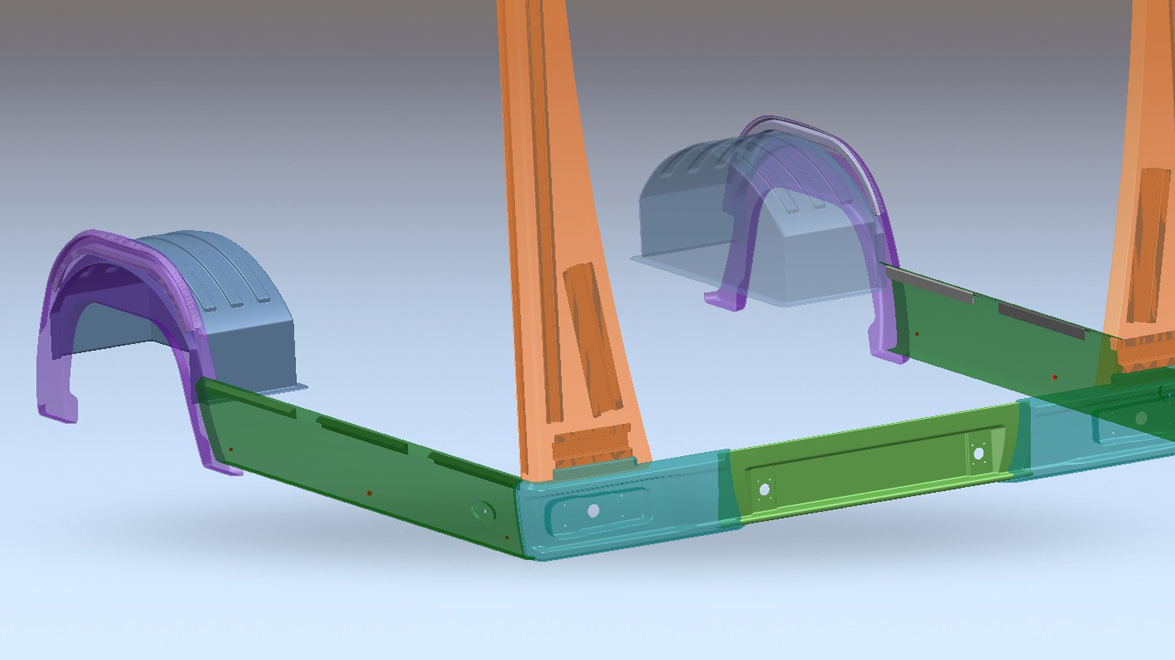

Utilising a combination of our own in-house tool making facilities and key external partners, ESP brings together our customers ideas and requirements from concept to full parts production. ESP can provide both prototype and production tooling from the simplest media, for small production batches, to complex CAD/CAM aluminium machined tools. All of our tooling is carefully stored and registered to be available for frequent or occasional use.

We also manufacture jigs and fixtures for accurate trimming, assembly and inspection of parts.